|

The role of silicon carbide in cast iron

1. Silicon carbide is a carbon-silicon compound. During the smelting process of molten iron, an appropriate amount of silicon carbide is added. Most of the carbon is burned, but silicon and a small amount of silicon carbide particles are integrated into the molten iron and become the core to promote graphite growth.

2. The finer the silicon carbide particles and the better the diffusion, the stronger the nuclear generation ability. The interface between the silicon carbide particles and the matrix is good. There are high-density dislocations around the particles. With the increase of crystals, the grain refinement is promoted, and the shape and length of the graphite are changed. The quantity is obviously improved, reducing the tendency of shrinkage cavity, improving the mechanical properties, air tightness and impermeability of castings.

3. During the addition of silicon carbide, due to the combustion of carbon, it also plays a part in deoxidation, reducing the occurrence of blowholes and slag inclusions in castings.

4. Silicon carbide also has the effect of promoting molten iron to increase carbon in the process of cooperating with the carbonization and smelting of scrap steel.

Supply granularity

0.5-5mm, 1-10mm, can be processed with various special sizes according to user requirements

Product packaging

25kg iron woven bag packaging plus ton bag packaging.

Quality assurance

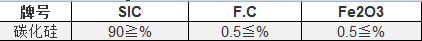

The product name and quantity are clearly marked on the packaging bag, and the corresponding product quality guarantee is provided.

|